About Tailings

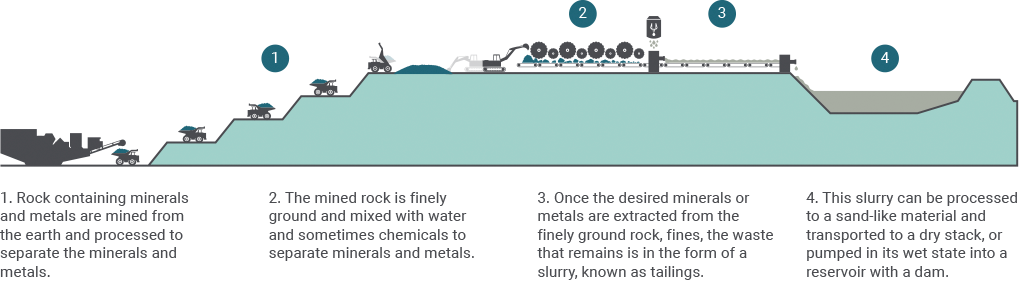

What are tailings?

Tailings is a common by-product of the process of extracting valuable minerals and metals from mined ore. They usually take the form of a liquid slurry made of fine mineral particles, created as mined ore is crushed, ground and processed. Effective tailings management is integral to the safe and sustainable production of metals and minerals.

Tailings can be stored in a variety of ways: which way depends on numerous factors, for instance the local topography, how much rainfall an area gets, whether there is regular or irregular seismic activity recorded, the type of mineral being mined and how close the mine is to populated areas. There is no one-size-fits-all solution, each tailings storage facility is unique.

Identifying the most appropriate method of tailings construction is important to ensure the safe and sustainable operation of a facility. Tailings storage facilities follow one of three wall construction designs: these are downstream, upstream and centreline.

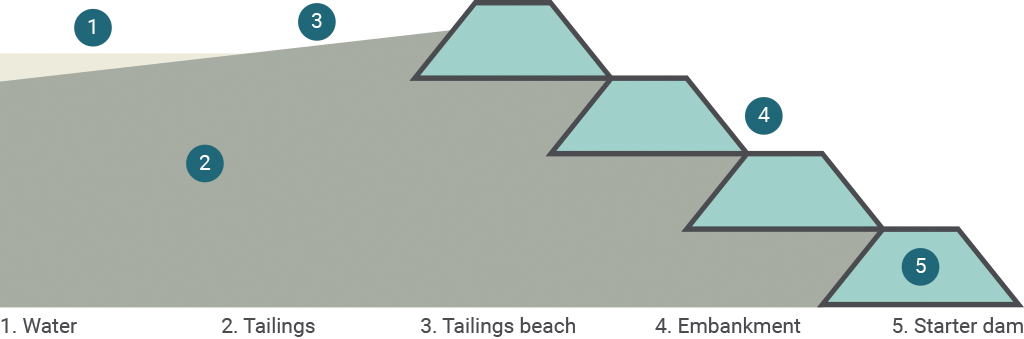

Downstream

Downstream designs start with an impervious starter dam. Tailings are then discharged into the dam and as the embankment is raised, each new wall is constructed and supported on top of the downstream slope of the previous section, so the dam crest moves downstream with each raise. The downstream design was developed for areas with seismic activity and high rainfall or water collection.

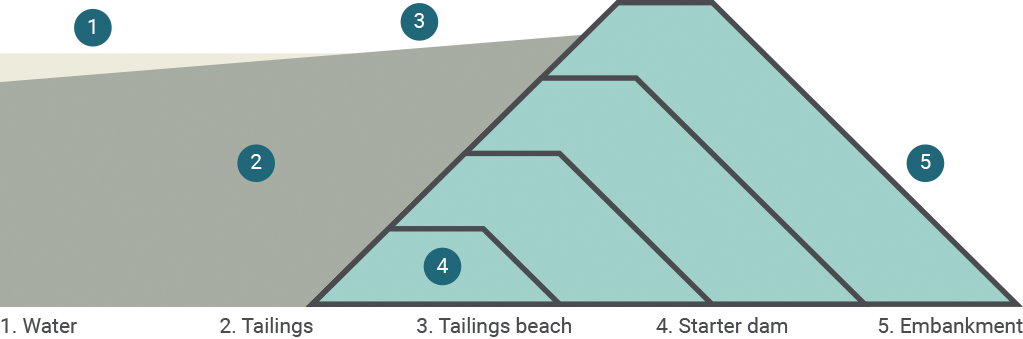

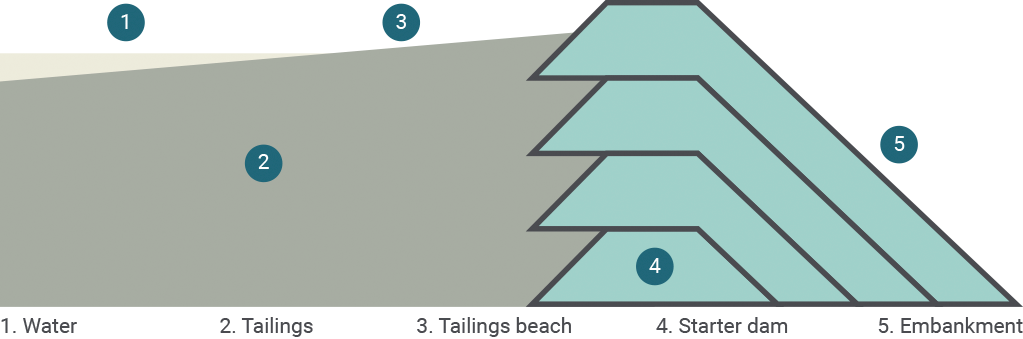

Upstream

Upstream construction begins with a starter dam. The tailings are then discharged into the facility where they form a tailings beach. The deposited tailings adjacent to the dam wall is allowed to drain and then can be compacted to be used to form the foundation for subsequent levels of the wall as the dam is raised. As such, the crest of the dam moves upstream with each raise.

Upstream tailings dams need to be raised slowly, to allow the solid tailings time to dry and consolidate enough to support a new level of the dam. These are suitable for facilities in areas of low rainfall and low seismic activity.

Centreline

The centreline method is a hybrid of upstream and downstream designs. In Centreline construction, the dam is raised vertically from the starter dam. The dam crest therefore remains fixed relative to upstream and downstream directions as the dam is sequentially raised. This design method can also incorporate internal drainage to improve stability.

Single Stage

A single stage dam is built to full height in one stage with no further raises. This design is most commonly used for smaller tailings facilities.

Managing tailings storage facilities effectively

For the most part, tailings storage facilities have been historically well-managed with few incidents of failure; however, when they do fail, the consequences can be catastrophic for communities, local economies and the surrounding environment. Responsible tailings management requires companies to consider the management and governance of tailings storage facilities from their design, construction, operation through to closure.

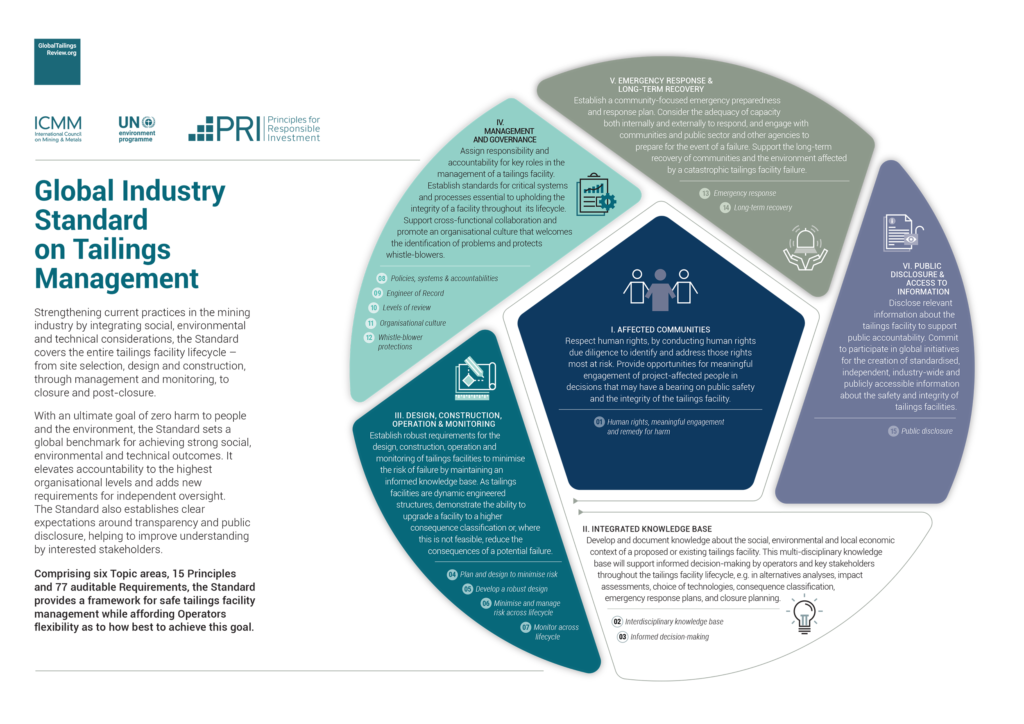

The Global Industry Standard on Tailings Management provides a framework for safer tailings facility management, while affording operators flexibility as to how best to achieve this goal.

See below an infographic summarising the Topic areas of the Standard: