Global Industry Standard on Tailings Management

“It is with great pleasure that I present the Global Industry Standard on Tailings Management, which sets a precedent for the safe management of tailings facilities, towards the goal of zero harm.

“The catastrophic dam collapse at Vale’s Corrego de Feijao mine in Brumadinho was a human and environmental tragedy that demanded decisive and appropriate action to enhance the safety and strengthen the governance of tailings facilities across the globe. I am particularly pleased to deliver a document which reflects and addresses the complexity and multi-disciplinary nature of sound tailings management.

“It has been a privilege to lead this work and I now call on all mining companies, governments and investors to use the Standard and to continue to work together to improve the safety of tailings facilities globally. It is my hope that the Standard will be supported by an independent body that can maintain the quality and further refine and strengthen the Standard over time.”

Dr Bruno Oberle, Chair: Global Tailings Review

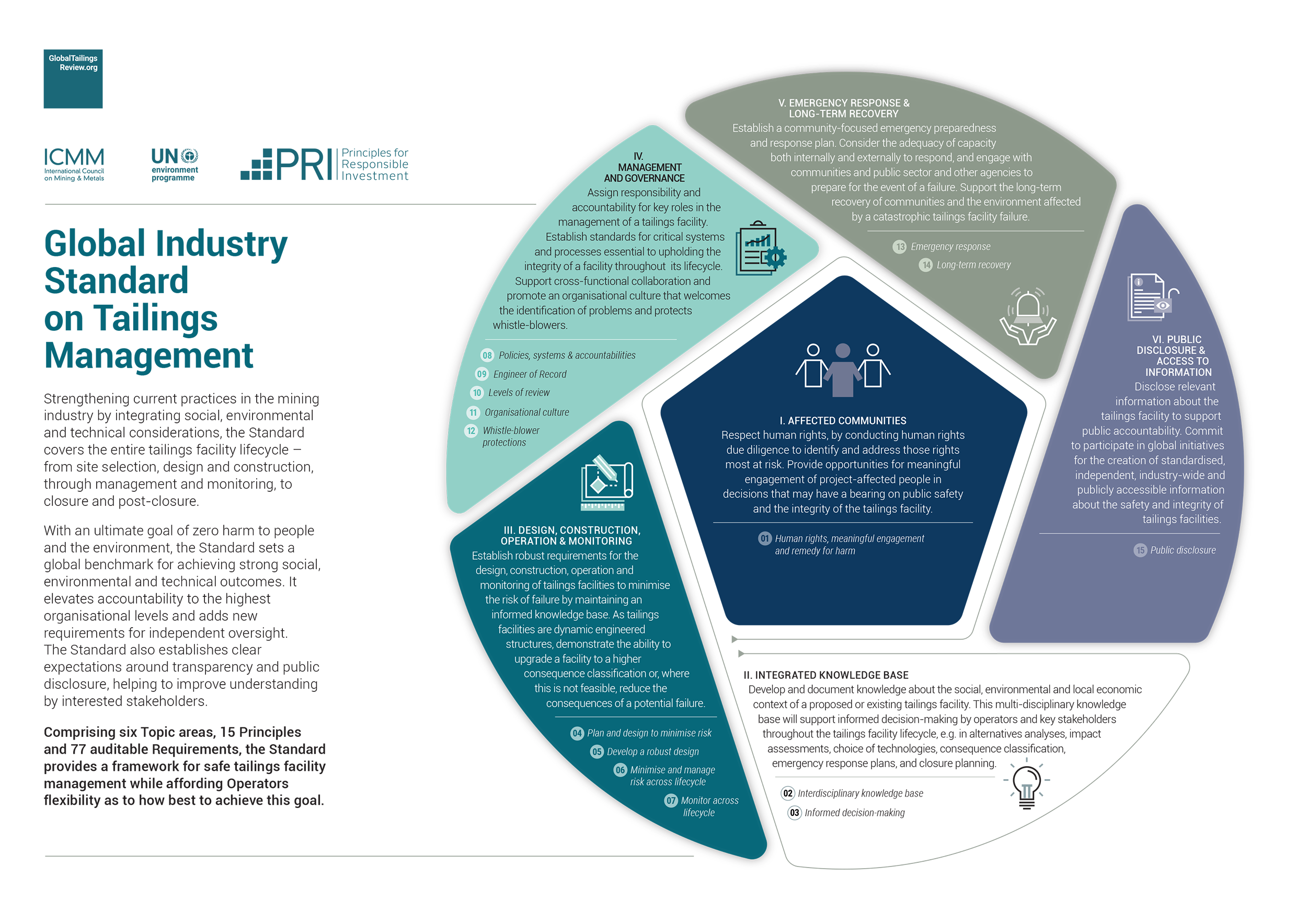

The Global Industry Standard on Tailings Management is directed at Operators[1] and applies to tailings facilities, both existing and to-be-built. It makes clear that extreme consequences to people and the environment from catastrophic tailings facility failures are unacceptable. Operators must have zero tolerance for human fatalities and strive for zero harm to people and the environment from the earliest phases of project conception. To be compliant with the Standard, Operators must use specified measures to prevent the catastrophic failure of tailings facilities and to implement best practices in planning, design, construction, operation, maintenance, monitoring, closure and post closure activities. Overall, conformance is expected where there is no conflict with the legislative requirements of the jurisdictions where tailings facilities are located.

It is important to note that future development of implementation protocols would clarify expected levels of performance.

The Standard’s structure is logical, not chronological. It is underpinned by an integrated approach to tailings management which was the overarching objective of the Panel. To give the Standard structure, the Requirements are organised around six Topic areas, 15 Principles and 77 auditable Requirements. The Standard also contains a detailed Glossary in Annex 1; Consequence Classification Tables in Annex 2; Annex 3 provides Summary Tables of key roles, functions, documents and levels of review mentioned in the Standard.

Topic Area I focuses on project-affected people. In order to respect human rights, including the individual and collective rights of indigenous and tribal peoples, a human rights due diligence process is required to identify and address those that are most at risk from a tailings facility or its potential failure. To demonstrate this respect, project-affected people must be afforded opportunities for meaningful engagement in decisions that affect them. The Requirements within Topic Area I are intended to be cross-cutting in terms of being addressed across all operational activities and ongoing throughout the tailings facility lifecycle.

Topic Area II requires Operators to develop knowledge about the social, environmental and local economic context of a proposed or existing tailings facility, and as part of this, to conduct a detailed site characterisation. It asks for a multi-disciplinary knowledge base to be developed and used by the Operator and key stakeholders in an iterative way to enable all parties to make informed decisions throughout the tailings facility lifecycle. These decisions will arise in the context of the alternatives analyses, the choice of technologies and facility designs, emergency response plans, and closure and post-closure plans, amongst others.

Topic Area III aims to lift the performance bar for designing, constructing, operating, maintaining, monitoring, and closing tailings facilities. Operators are asked to demonstrate the ability to upgrade a facility at a later stage to a higher consequence classification. For existing facilities, where upgrading is not feasible, the Operator must reduce the consequences of a potential failure. Recognising that tailings facilities are dynamic engineered structures, Topic Area III requires the ongoing use of an updated knowledge base, consideration of alternative tailings technologies, the use of robust designs and well-managed construction and operation processes to minimise the risk of failure. A comprehensive monitoring system must support the full implementation of the Observational Method and a performance-based approach must be taken for the design, construction and operation of tailings facilities.

Topic Area IV focuses on the ongoing management and governance of a tailings facility. It provides for the designation and assignment of responsibility to key roles in tailings facility management, including an Accountable Executive, an Engineer of Record and a Responsible Tailings Facility Engineer. Further, it sets standards for critical systems and processes, such as the Tailings Management System and independent reviews, which are essential to upholding the integrity of a tailings facility throughout its lifecycle. Cross-functional collaboration and the development of a learning organisational culture that welcomes the identification of problems and protects whistle-blowers are also included.

Topic Area V covers emergency preparedness and response in the event of a tailings facility failure. Operators must avoid complacency about the demands that would be placed on them in the event of a catastrophic failure. The Standard requires Operators to consider their own capacity in conjunction with that of other parties, and to plan ahead, build capacity and work collaboratively with other parties, in particular communities, to prepare for the unlikely case of a failure. Topic Area V also outlines the fundamental obligations of the Operator in the long-term recovery of affected communities in the event of a catastrophic failure.

Topic Area VI requires public disclosure of information about tailings facilities to support public accountability, while protecting Operators from the need to disclose confidential commercial or financial information. The Standard concludes by requiring that Operators commit to transparency, and participate in global initiatives to create standardised, independent, industry-wide and publicly accessible information about tailings facilities.

[1] The Standard defines ‘Operator’ as: an entity that singly, or jointly with other entities, exercises ultimate control of a tailings facility. This may include a corporation, partnership, owner, affiliate, subsidiary, joint venture, or other entity, including any State agency, that controls a tailings facility.